No flash floods at Berlin’s new Airport

Our climate may be changing but could plastic pipe technology offset all the many adverse effects of deluge followed by desiccation? The answer may well lie beneath our feet. Berlin’s new airport is to become a showcase for this technology and Europe is taking note.

When the new Berlin-Brandenburg International Airport opened in 2011, it benefited from one of the largest rainwater infiltration schemes in Europe. Typically, airports require a labyrinth of costly drainage pipes and tunnels to maintain rainwater run-off from their open and exposed surfaces. However, this scheme mitigates flooding and land subsidence through harvesting rainwater from runways, perimeter and access roads and then releasing it gradually.

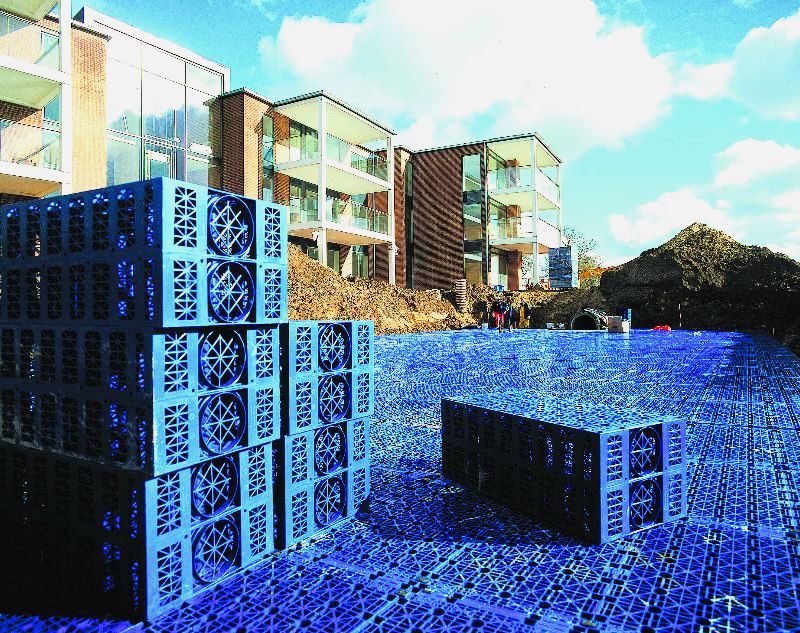

Light weight and easy to install, the units (600 x 600 x 1,200 mm) were installed in two layers within a pit configuration that measured 22 meters wide by 330 meters long. Made from a special polypropylene, they are specifically designed to facilitate inspection and maintenance.

Over 100 truckloads were required to transport the infiltration units and ancillary equipment such as plastic manholes, drainage pipes and fittings. However, installation of almost 2,000 of these units was carried out in a matter of days and without the use of heavy lifting equipment.

Once the airport was completed, it replaced three existing airports in the Berlin area. It embraced a surface area equivalent to 2000 football fields and now serves an estimated 30 million passengers per year. Above ground, its air traffic provides a long awaited improvement to the nation’s communication links with the rest of Europe. Below ground, it has a sustainable system for rainwater management that will endure for at least 50 years.