The Berlin Water Trade Fair provided an international window for ingenious technology in the field of water management. But how to show the visitors to the Fair in one day only, exactly how easy and without any disruption these kind of plastic solutions are?

That was the challenge that a German engineering firm set itself.

Old Pipe Made New

The firm was Ludwig Pfeiffer Hoch-und Tiefbau GmbH & Co. KG. Its engineers did not have to look far to find a pipe that was in need of urgent renovation. The local Berlin water companies had a perfect candidate in the form of an old 1200 m wrought iron pressure wastewater pipe. The antiquated pipe was situated beneath a busy residential and commercial district with shops and restaurants and a fair amount of road traffic. Disruption here in the form of open excavation would have proved lengthy and very expensive.

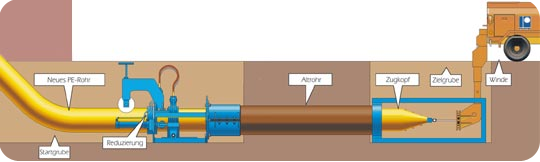

However, the plastic solution chosen for what became known as the Friedensstrasse project was “sewage lining”. Sewage lining allows a new, tight-fitting polyethylene (PE) pipe to be placed inside new or existing pipelines. The system uses a PE pipe which has an outside diameter slightly larger than the inside diameter of the pipe to be lined. After sections of PE are fused together to form a continuous pipe, the PE pipe is pulled through a reduction die, which temporarily reduces its diameter.

This allows the PE pipe to be pulled through the existing pipeline. After the PE pipe has been pulled completely through the pipe, the pulling force is removed and the PE pipe returns toward its original diameter until it presses tightly against the inside wall of the host pipe. The tight fitting PE liner results in a flow capacity close to the original pipeline design.

The Friedensstrasse project involved inserting a PE liner into the old DN 1000 mm pipe in two phases. It was therefore only necessary to dig three building pits around which the road traffic could be easily directed.

Renovation of the pipeline took place in two phases of 322 m and 216 m. The old pipeline was separated at the one start pit and then at the remaining two pits. High pressure cleaning to flush out removable deposits was followed by CCTV inspection. Solid incrusts were removed through mechanical scratching. Any remaining obstacles were removed by a milling robot.

The old pipe was now ready to be lined with PE pipes with DN 1030 x 60.6 mm. These pipes were first connected using butt-welding and then pulled through the sewage lining die. Having been reduced by a around ten percent in diameter, the liner expanded by about 5% owing to relaxation through the memory effect.

Longer Service Life

In the course of twenty four hours, the old pipe was renovated with a liner that has all the quality of a new pipe. It could therefore carry all loads from the ground and traffic, as well as the internal pressure without effects from the old pipe. Furthermore, the very good hydraulic characteristics of PE-pipes are such that any further flow reduction was not expected.

The speed of deformation and insertion was between 50 and 100 m per hour which is common for pipes of such a diameter. This means that below ground it is possible to install pipelines of 300 to 600 mm easily in one day. It also means that above ground, disruption is minimised.

PE pipes that are used for the sewage lining process are manufactured according to DIN, ISO, AGA, ASTM or API standards. This ensures that they have defined physical properties and will perform over a long specified service life. There is no shrinking or hardening and no chemistry required on the construction site. Moreover, polyethylene is flexible, leak tight and highly resistant to chemical attack.

This process is suitable for all pipelines within the range of diameters DN 65 to DN 1200 m. Up to 1000 meters can thus be renovated in one length depending on the traction forces that occur. It can be successfully used to renovate pressure and non-pressure pipelines not only in the sewer sector but also in water and gas distribution, petrochemicals and offshore industries.